CHLORINE FREE METALWORKING FLUID FOR HIGH PRESSURE MACHINES

VP690 is a macro emulsion metalworking fluid designed for high pressure coolant applications. The product is found in systems with pistons and positive displacement pumps that increase coolant pressure up to 2000 psi. VP690 is a chlorine free product that was designed for aerospace, medical, nuclear, and all other industries that are sensitive to chlorine stress cracking. The product provides “soluble-oil” performance with sump stability that approaches that of a synthetic product. The product is non-irritating to workers’ skin and will not cause dermatitis issues. VP690 provides excellent rust protection due to a proprietary manufactured tri-phase corrosion inhibitor package.

- Chlorine, sulfur, phenol and boron free

- Excellent Foam Suppression

- Extended tool life with increased production rates

- Best in class resistance to bacteria growth

- Exceptional tramp oil rejection

- Outstanding surface finish

- Non-irritating to operators’ skin

- Steel

- Cast Iron

- Stainless Steel

- High Temp Alloys

- Titanium

- Aluminum

- Copper

- Brass

- Nickel Alloys

- High Carbon

- Plastics

- Inconel

See the most recent SDS which is available directly from ValCOOL, your local representative or authorized distributor. ValCOOL uses only raw materials not listed as carcinogenic by IRAC.

Appearance:

Diluted Appearance:

Solubility:

Odor:

Specific Gravity:

Concentrate pH:

pH, 5 % dilution:

Freeze/Thaw Cycles:

Clear Amber Liquid

Milky Amber Liquid

Milky Macro-Emulsion

Mild Industrial

.98

9.4

9.3

Passed 3x

ValCOOL recommends using Val-U-Clean or K-5-P cleaner before adding VP690 to a machine.

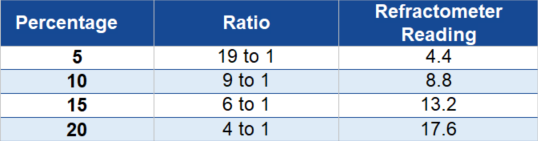

The recommended concentration for VP690 is 5-10% for optimum results. However, results for any operation can only be determined through testing.

Maintaining the coolant at its optimum concentration is achieved through daily refractive index checking.

No special precautions are necessary with respect to seals or valves.

1.1 x multiplier

Fluid compatibility and machinability should always be tested first; as fluid concentration, metal alloy, and machining operation are variable.